US manufacturing is experiencing unprecedented growth with the CHIPS Act driving $52 billion in semiconductor investment and supply chain reshoring accelerating domestic production. However, 73% of manufacturing plants still rely on legacy Manufacturing Execution Systems (MES) that cannot integrate with modern IIoT devices, cloud platforms, or AI-driven analytics. These outdated systems create bottlenecks that directly impact productivity, compliance, and competitiveness in today's fast-moving industrial landscape.

The critical challenge lies in modernizing these mission-critical systems without disrupting production. Any downtime can cost manufacturers millions in lost revenue, regulatory violations, and market share. This is where specialized digital product engineering services become essential providing the expertise to transform legacy MES infrastructure with zero operational disruption while ensuring full compliance with US manufacturing standards.

The Legacy MES Crisis Threatening US Manufacturing

Legacy MES systems built 10-20 years ago using monolithic architectures have become significant barriers to growth. These systems suffer from fundamental design limitations that prevent manufacturers from adapting to modern business requirements and regulatory demands.

Critical system limitations include :

Proprietary protocols that block integration with modern robotics and sensors.

Batch data processing causing 2-4 hour delays in critical decision-making.

Hard-coded business logic preventing rapid compliance updates.

Outdated security models failing NIST Cybersecurity Framework requirements.

The financial impact is staggering. Recent manufacturing surveys reveal that delayed MES modernization costs US plants $2.1 million annually in lost productivity per facility, along with 15-25% higher regulatory compliance costs and 40% longer new product introduction cycles. For manufacturers competing in global markets, these inefficiencies can be fatal to long-term viability.

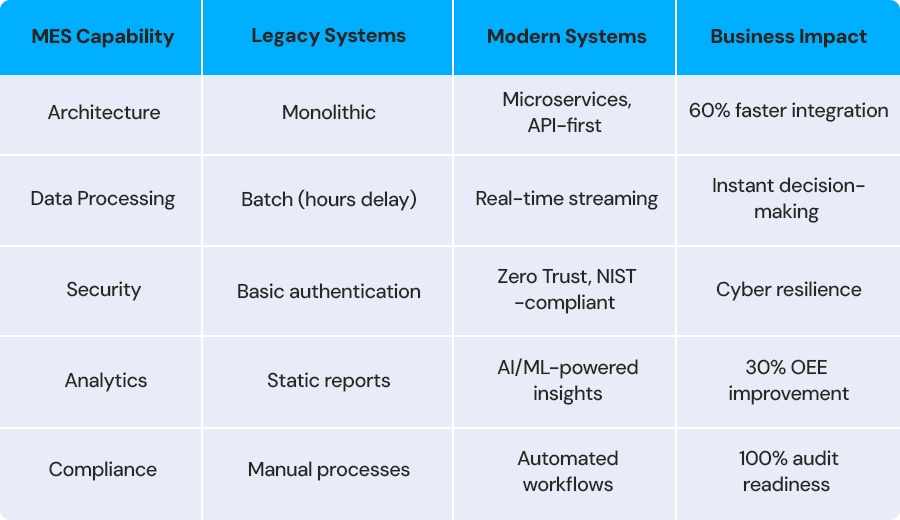

Modern MES: The Foundation for Smart Manufacturing

Today's manufacturing environment demands systems built on cloud-native architectures that prioritize flexibility, scalability, and real-time data processing. Modern MES platforms serve as the central nervous system for smart factories, orchestrating complex interactions between machines, operators, and business systems while maintaining the highest levels of security and compliance.

The transformation extends beyond technology upgrades to encompass operational excellence and regulatory compliance. Modern systems must align with established manufacturing standards including MESA-11 functional requirements and ISA-95 integration architecture. These frameworks ensure that modernization efforts preserve critical manufacturing capabilities while enabling future digital transformation initiatives.

MESA-11 functions maintained during modernization:

Resource allocation and operations scheduling.

Real-time data collection and quality management.

Product tracking, genealogy, and performance analysis.

Automated maintenance and labor management .

Zero-Downtime Modernization Through Product Engineering Services

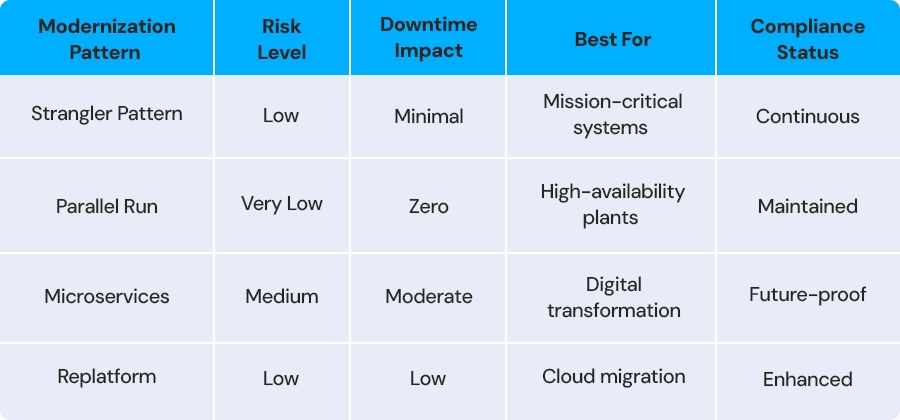

The cornerstone of successful MES modernization lies in meticulous planning and risk mitigation strategies developed through years of manufacturing transformation experience. Professional product engineering services have refined methodologies that eliminate traditional risks associated with system upgrades while ensuring operational continuity throughout the transformation process.

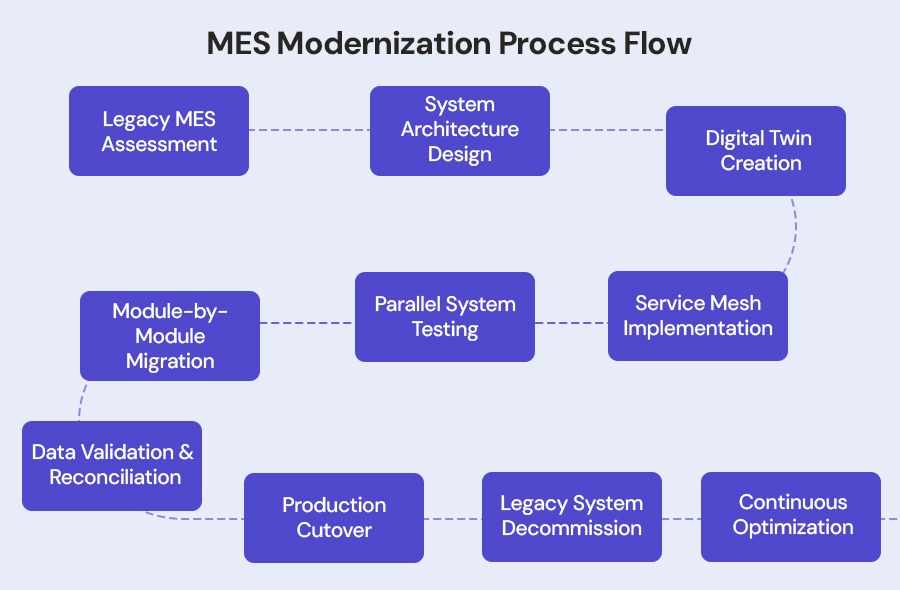

The comprehensive approach begins with detailed system analysis including automated dependency mapping of all MES interfaces, digital twin creation for complete system simulation, and custom code analysis covering VB6 macros, database triggers, and embedded scripts. This thorough assessment identifies potential failure points and develops mitigation strategies before any production systems are modified.

MES Modernization Process Flow

The proven three-phase implementation strategy has been successfully applied across automotive, pharmaceutical, and electronics manufacturing sectors. Phase one creates a service mesh wrapping legacy APIs with modern service layers while establishing secure communication protocols. Phase two implements modular replacement of individual functions like reporting, genealogy, and WIP tracking through microservices with full API integration. Phase three executes validation and cutover through shadow testing with live production data and automated reconciliation.

Real-World Success Stories from US Manufacturing

A major automotive assembly plant in Michigan faced critical challenges with legacy MES that couldn't provide real-time traceability for safety-critical components, risking NHTSA compliance violations. The modernization required exceptional precision as every weld point and quality check needed real-time tracking without interrupting continuous production flow.

The product engineering solution involved creating comprehensive digital twins of all critical processes before physical system changes. The team implemented microservices replacement starting with the QA module, followed by progressive modernization of genealogy and performance reporting systems. Results exceeded expectations with zero production downtime during the 8-week modernization, 100% paperless compliance achievement, real-time component traceability to ERP systems, and $1.8 million in annual savings from automated quality processes.

Similarly, a New Jersey pharmaceutical facility required FDA 21 CFR Part 11 compliance for batch record requirements without risking multi-million dollar batch losses. The solution involved parallel deployment of modern batch record microservices while maintaining legacy systems for audit compliance during transition. The 12-week migration achieved full FDA digital signature compliance, real-time exception management, zero batch interruptions, and 60% reduction in compliance documentation time.

Advanced Integration Meeting US Regulatory Standards

Modern manufacturing demands seamless OT/IT convergence while maintaining security and reliability that production operations require. This integration extends beyond technical connectivity to encompass cybersecurity frameworks protecting both production systems and corporate networks from increasingly sophisticated cyber attacks.

NIST Cybersecurity Framework implementation includes:

Zero Trust architecture deployment across all manufacturing systems.

Real-time threat monitoring and automated response capabilities.

Multi-factor authentication for all system access points.

Automated patch management with tested rollback protocols.

Industrial edge integration leverages OPC-UA and MQTT protocols for low-latency communication, edge AI deployment for predictive analytics, and secure cloud connectivity for remote monitoring and support. This architecture enables real-time data flow from shop floor sensors through manufacturing systems to enterprise planning applications.

Compliance-first modernization addresses multiple regulatory frameworks simultaneously. FDA 21 CFR Part 11 readiness includes electronic signature implementation, automated audit trails, and secure data archival. OSHA digital safety integration provides real-time monitoring dashboards, automated incident reporting, and mobile work instruction delivery. EPA environmental compliance automates data collection, emissions monitoring, and regulatory reporting processes.

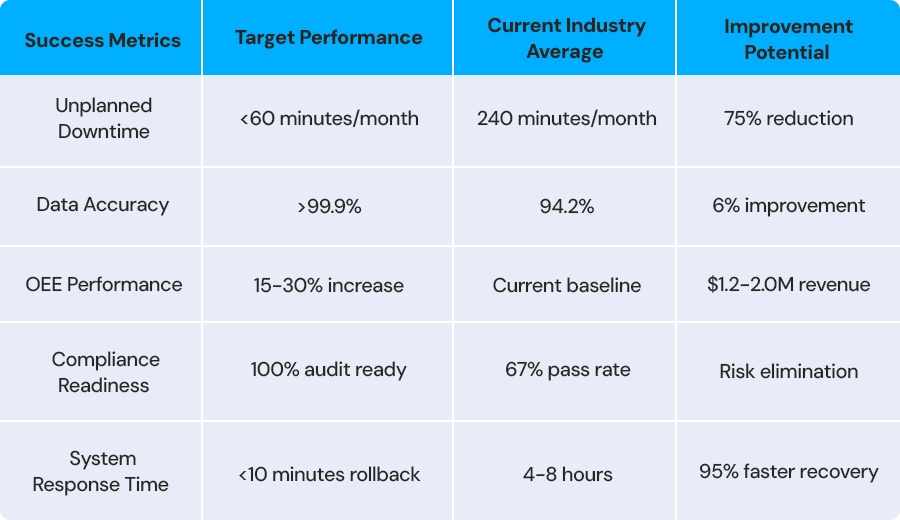

Implementation and Success Metrics

Successful MES modernization requires careful orchestration balancing modernization urgency with absolute production continuity requirements. The structured approach creates multiple validation checkpoints ensuring new systems meet all functional and performance requirements before full deployment.

The typical modernization project spans 6-9 months with structured phases including assessment and architecture design, pilot implementation, parallel operation, phased cutover, and ongoing optimization. Each phase delivers specific outcomes from modernization roadmaps and ROI projections through proof of concept validation to fully modernized MES deployment.

Strategic Investment ROI and Business Impact

Manufacturing executives require clear financial justification for MES modernization investments given project scale and complexity. The business case demonstrates immediate operational improvements alongside long-term strategic value and competitive positioning through detailed ROI analysis and performance modeling.

First-year impact typically includes 15-25% OEE improvement generating $1.2-2.0 million additional revenue, 40% compliance cost reduction saving $300-500K, and 90% downtime elimination protecting $800K-1.5 million in revenue. Three-year projections encompass digital transformation readiness worth $2-5 million in AI/ML efficiency gains, competitive advantages supporting 10-15% market share growth, and regulatory future-proofing for emerging compliance standards.

Investment protection mechanisms ensure long-term value :

Modular architecture enabling easy upgrades without complete replacement.

Open standards implementation preventing vendor lock-in situations.

Scalable design accommodating growth without architectural overhaul.

Security-first approach maintaining cyber resilience for operational continuity.

Product Engineering Services: Your Modernization Partner

Successful MES modernization requires multidisciplinary expertise spanning manufacturing operations, regulatory requirements, and complex system integration. Product engineering services providers bring proven methodologies, deep industry knowledge, and comprehensive support ensuring technical solutions align with operational realities and business objectives.

The value proposition extends beyond initial implementation to encompass long-term system evolution and optimization. Manufacturing environments constantly change with new regulations, technologies, and business requirements emerging regularly. The right engineering partner provides strategic guidance and technical capability for ongoing adaptation and evolution.

Comprehensive expertise includes:

Architecture consulting for microservices design and cloud-native deployment.

Custom software engineering for module development and legacy integration.

Security engineering implementing Zero Trust and NIST framework compliance.

System integration connecting ERP, PLM, SCADA, and IoT sensor platforms.

Post-modernization support encompasses operator training programs, digital work instruction development, disaster recovery planning, 24/7 monitoring services, performance optimization, and emerging technology integration planning. This comprehensive approach ensures sustained value realization and competitive advantage maintenance.

Getting Started: Modernization Readiness Assessment

Beginning MES modernization requires honest evaluation of technical and organizational readiness. Manufacturing leaders must assess current capabilities, constraints, and objectives before committing to multi-month transformation projects. The most successful modernizations begin with comprehensive readiness assessment identifying potential challenges and mitigation strategies.

Critical readiness factors include :

Current system documentation completeness and accuracy.

Integration complexity with existing plant floor systems.

IT/OT team collaboration maturity and cross-training needs.

Cybersecurity baseline assessment and improvement requirements.

Business readiness encompasses production schedule flexibility for parallel testing, operator training program capacity, change management process maturity, and phased implementation budget allocation. Each factor influences modernization approach and timeline requirements.

Selecting the right product engineering services partner represents the most critical decision in the modernization process. The ideal partner combines technical expertise with deep manufacturing domain knowledge, proven methodologies, and operational experience navigating complex industrial environments. Success indicators include portfolios of similar manufacturing modernizations, strong OT/IT convergence experience, established MES vendor partnerships, and comprehensive security and compliance expertise.

Future-Proofing American Manufacturing Excellence

The manufacturing landscape continues evolving through artificial intelligence, edge computing, and industrial automation advances. Modern MES modernization must anticipate these trends and create architectural foundations accommodating future technological developments without requiring complete system overhauls.

Edge AI and machine learning capabilities enable autonomous line balancing, predictive maintenance scheduling, yield improvement through pattern recognition, and quality anomaly detection. Digital twin evolution supports complete plant simulation, change impact analysis, continuous improvement modeling, and virtual commissioning for new equipment. Universal event architecture provides plug-and-play module replacement, seamless upgrade pathways, reduced future complexity, and enhanced system resilience.

US manufacturing reshoring initiatives create new opportunities and challenges for MES systems supporting distributed supply chains while maintaining agility for market volatility response. Critical capabilities include real-time supplier performance monitoring, automated inventory optimization, supply chain disruption response, and multi-jurisdiction regulatory compliance.

Conclusion: Seizing the Manufacturing Modernization Opportunity

American manufacturing leadership depends on decisions being made today regarding technology infrastructure and operational capabilities. Legacy MES systems have become barriers to growth, efficiency, and competitiveness in today's rapidly evolving industrial landscape, making modernization a strategic imperative rather than an option.

Professional product engineering services provide specialized expertise, proven methodologies, and comprehensive support needed for zero-downtime modernization while future-proofing operations. The investment in expert guidance pays dividends through reduced risk, faster time-to-value, and enhanced long-term operational capabilities that position manufacturers for sustained competitive advantage.

TL:DR: Legacy MES Modernization Without Downtime

Challenge: 73% of US manufacturers use legacy MES systems that can't integrate with modern IIoT, costing $2.1M annually per facility in lost productivity

Solution: Digital product engineering services enable zero-downtime modernization through strangler patterns, parallel operations, and microservices architecture

Benefits: 15-30% OEE improvement, 100% compliance readiness, $1.2-2.0M additional revenue, and 90% downtime reduction during modernization

Approach: Three-phase implementation with digital twins, automated testing, and phased cutover by production line

Investment: First-year ROI includes $800K-1.5M protected revenue and 40% compliance cost reduction

Success Factors: Choose product engineering partners with manufacturing domain expertise, proven zero-downtime methodology, and comprehensive post-implementation support

Write a comment ...